The unmanned remote control system for tower cranes is an intelligent remote control system based on the Internet of Things, big data, artificial intelligence, remote control systems, remote scheduling systems, security inspection systems, and environmental awareness. The remote driving system of the tower crane will henceforth bid farewell to the dangers and unsafe factors brought by the driver when climbing the tower, such as rain, snow, and ice on the ladder.

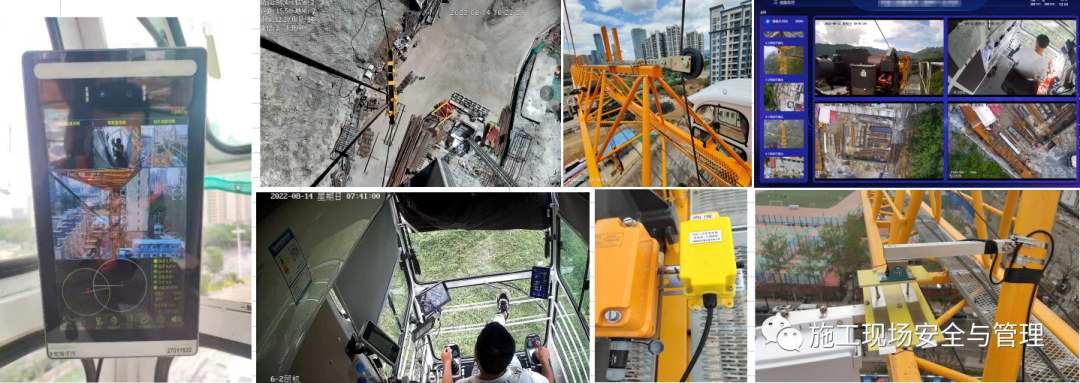

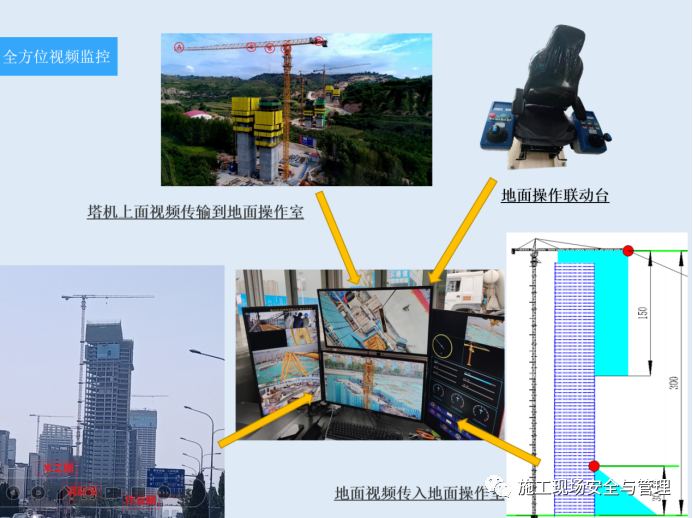

All-round video monitoring

It can provide full coverage of lifting mechanism video, luffing mechanism video, boom tip panoramic video, tower top panoramic video, cab video, boom tip automatic hook following video, car video, steel shed, woodworking shed, and other video blind areas without dead spots.

Intelligent linkage console

Fully monitor and control the functions of the tower crane such as general start (with self-locking function), emergency stop, slewing brake, fan (three mechanisms), electric bell, wind indicator, bypass, lifting brake, etc., and integrate dual eddy current dedicated delay relays. In addition, it can monitor and configure the full range of parameters of the frequency converter. Three sets of inverter operating parameters, namely, extreme speed, constant speed, and ant speed, effectively improve the lifting efficiency. In addition, remote shutdown, speed reduction, and restart functions facilitate the management of drivers.

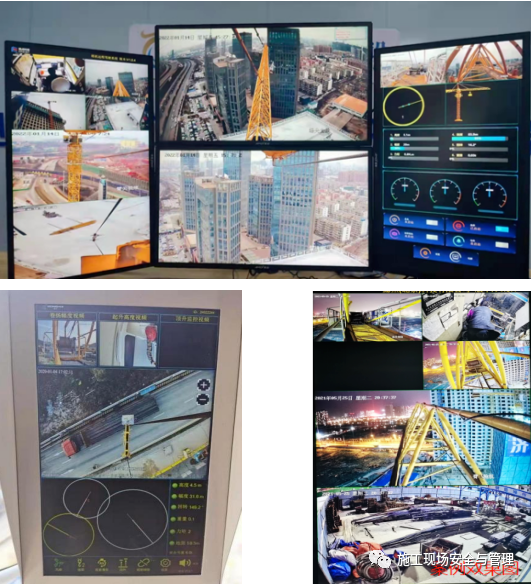

Comprehensive data monitoring

It can comprehensively monitor parameters such as amplitude, height, rotation, weight, torque, wind speed, inclination angle, position, temperature and humidity, current, and power operation frequency to make driving safer.

Tower crane safety monitoring system+hook blind area visualization system comprehensively assist the driver in lifting more safely!

Through various precision sensors, real-time collection of height, amplitude, weight, torque, rotation, wind speed, tower group anti-collision, hazardous area protection, and other real-time data during tower crane operations is conducted. Through the display screen in the cab, the current actual working parameter values are displayed in graphic and voice mode, and sound and light warnings and alarms are issued in advance! Let the driver intuitively understand the working status of the tower crane, correctly operate the tower crane, and eliminate potential safety hazards!